Published on Nov 30, 2023

Improper management of wastes are responsible for the accumulation of MSW at every nook and corner. Composting of organic fraction is the major route for recycling. The present research work is focused on composting of Mysore’s market wet waste. Mysore city generates about 402 tonne of MSW every day, out of which 60% is wet waste.

Keywords : Municipal solid waste, In-vessel composter, Total Organic Carbon and C/N ratio

The main objective is to design of in-vessel aerobic compost reactor to treat Devaraja market solid waste.

To assess the generation rate of market waste

To determine the composition and physico-chemical characteristics of market waste

To design a lab-scale aerobic in-vessel compost reactor and

To monitor the nutrient contents (NPK values) & C/N ratio

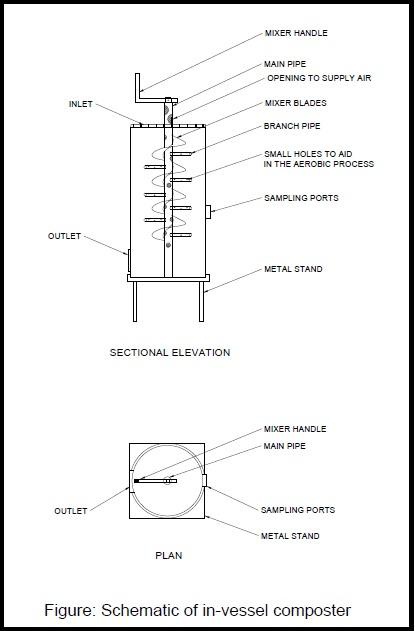

A bench scale rotary drum made up of PVC is used as composter in the present work and the same is indicated in schematic. Microbial consortium is added to the composter in sufficient quantity to facilitate composting process. Temperature was monitored at regular intervals. Representative samples of composting materials were collected through sampling ports provided at different levels of composter to study the process parameters. The humus was dried, ground and analyzed for the physico- chemical parameters such as moisture content, volatile solids, total organic carbon(TOC) and total kjeldhal nitrogen(TKN) to assess the quality of the compost.

HDPE drums, mixer blade and steel pipes

In-Vessel Composter

Based on the studies carried out and the observations made in the present research, the following conclusions are drawn,

The survey conducted in the market area showed that, on an average about 4.8 – 5.6 ton of waste per day is generated in Devaraja market

From the total quantity of waste, about 90-92% was biodegradable and 5-8% of non-biodegradable wastes are generated in market. Out of which, total organic fractions consists of 50-60% of vegetable waste, 20-30% of fruit waste and 2-5% of paper waste

Proportions of bulking agent may be varied to compensate the moisture content and its effect on composting process can be studied

Effect of varying proportion of seeding material on composting process can be studied.

Total Phosphorus content (P) of the compost of Cycle 1 and Cycle 2 are 0.1% and 0.4% respectively

Total Potassium content (K) of the compost was found to be 2.4% and 2.1% , which possess the sufficient nutrient value

C/N ratio of finished compost for both cycles are 15 and 16 respectively, which are less than the standard value 30

Composter was found to be effective, as no operational problem, no odour and vectors were observed and all nutrients are meeting the required valves, it can be concluded that the compost produced with the designed composter is of good quality