Published on Nov 30, 2023

Biodiesel is a good alternative for fossil fuel. In recent years, biodiesel production from vegetable oils and animal fats has gained attention because of its eco-friendly nature, liquid nature, and easy portability. However, biodiesel is more expensive than fossil fuels, which limits its applications. The major production cost of biodiesel is from its feedstock. The foremost problem that the biodiesel industry faces nowadays is the availability of low-cost and good quality feedstock. To meet this problem, industries use waste vegetable oil and grease and animal fats from poultry to produce low-cost biodiesel. In addition, researchers are developing certain crops with high oil content just for the production of biodiesel. In this work, we have demonstrated that spent coffee grounds can be a potential source for the production of biodiesel as well as fuel pellets.

Coffee is one of the largest agricultural products that is mainly used for beverages. The residue after brewing the coffee grounds is oil containing waste material and has a potential to be used as a biodiesel feedstock.

In India total coffee production is 3, 55,600 tonnes, out of which most of the production gain is expected to come from Karnataka where the total coffee output is pegged at 2, 56,500 tonnes in 2015-16. This is quite significant as compared to other major biodiesel feed stocks such as rapeseed oil (37-50%), palm oil (20%), and soybean oil (20%). This can add approximately 340 million gallons of biodiesel to the world’s fuel supply. The remaining solid waste can be utilized as compost as a feedstock and as fuel pellets.

Keywords : Biodiesel, Spent Coffee , vegetable oil, hexane

1. To extract the oil from spent coffee grounds using hexane as a solvent.

2. To analyze the properties of extracted oil.

3. To study energy availability by the conversion of spent coffee grounds to biomass and bio-fuel.

The materials used in this project work are spent coffee grounds and Hexane. SCG is used as sample from which oil is extracted where as hexane is used as a solvent for oil extraction.

1) Soxhlet Extraction Method.

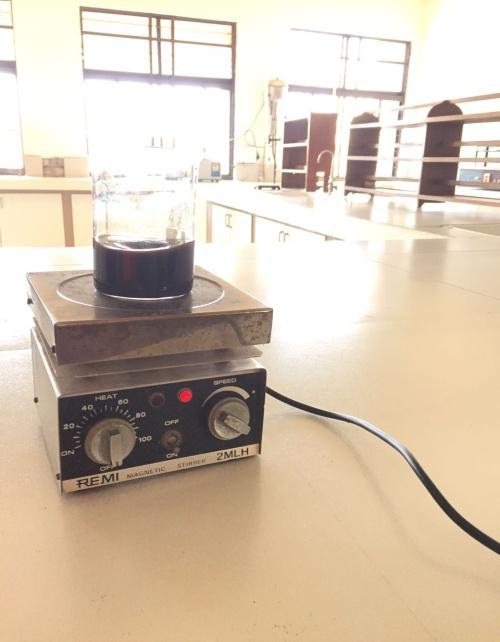

2) Response Surface Method (Magnetic Stirrer).

We have adopted Response Surface Method as this method results more yield and consume less time than compare to Soxhlet Extraction Method.

• In this method mass ratios of Dried Spent Coffee Grounds (DSCG) to hexane are varied under the Experimental design matrixes.

• The magnetic bar is instantaneously put into the flask to mix the DSCG with hexane.

• In the coffee oil extraction process, the flask is placed on the digital magnetic stir plate to mix the DSCG with solvent by the magnetic stirrer at room temperature.

• Immediately start the timer to monitor the extraction time.

• After complete Extraction oil, the Oil Free Spent Coffee Grounds (OFSCG) will rapidly fall to the bottom of the flask and the solutions of Hexane-to-coffee oil is on the top layer.

• The suspensions are filtered by the filter paper to separate the OFSCG and solutions.

• In hexane distillation process, the solutions of Hexane-to-coffee Oils are stilled by simple distillation process to remove the most hexane.

• In the final process the coffee oil from the distillation process will be heated to remove the residual hexane which might also be left in the coffee oil.

1. The spent coffee grounds have been successfully converted into a potential source to produce biodiesel and its by-products as fuel pellets.

2. Oil extraction with a mixture of SCG/hexane (1:20) (wt/wt) that allowed for the higher oil recovery at a relatively lower cost was converted to biodiesel with 15-20 % yield and remaining 75-80% as a biomass.

3. The extracted oil was analyzed and obtained results as per ASTM standards.

4. The solid waste remaining after oil extraction , which is the by-product from the biodiesel production, is experimentally proven to be promising raw material for producing fuel pellets.

5. The production of the solid waste after oil extraction can also promote a zero waste approach for the biodiesel production process.

1. Design manufacturing process for biofuel and biomass pellets from spent coffee grounds.

2. Determine plant location based on ease and volume of spent coffee ground transport.

3. Analyze profitability given reasonable estimates of coffee supply and fuel costs.

4. Obtain final product whose energy and cost is comparable to existing biofuels and Alternative fuel sources.

5. Maintain process integrity by following good manufacturing practices, maximising materials recycling and being environmentally friendly.