Published on Apr 02, 2024

Evolutionary changes in the regulatory and operational climate of traditional electric utilities and the emergence of smaller generating systems such as microturbines have opened new opportunities for on-site power generation by electricity users. In this context, distributed energy resources (DER) - small power generators typically located at users' sites where the energy (both electric and thermal) they generate is used - have emerged as a promising option to meet growing customer needs for electric power with an emphasis on reliability and power quality.

The portfolio of DER includes generators, energy storage, load control, and, for certain classes of systems, advanced power electronic interfaces between the generators and the bulk power provider. This paper proposes that the significant potential of smaller DER to meet customers' and utilities' needs, can be best captured by organizing these resources into MicroGrids.

MicroGrid concept assumes an aggregation of loads and microsources operating as a single system providing both power and heat. The majority of the microsources must be power electronic based to provide the required flexibility to insure operation as a single aggregated system. This control flexibility allows the MicroGrid to present itself to the bulk power system as a single controlled unit that meets local needs for reliability and security.

The MicroGrid would most likely exist on a small, dense group of contiguous geographic sites that exchange electrical energy through a low voltage (e.g., 480 V) network and heat through exchange of working fluids. In the commercial sector, heat loads may well be absorption cooling. The generators and loads within the cluster are placed and coordinated to minimize the joint cost of serving electricity and heat demand, given prevailing market conditions, while operating safely and maintaining power balance and quality. MicroGrids move the PQR choice closer to the end uses and permits it to match the end user's needs more effectively. MicroGrids can, therefore, improve the overall efficiency of electricity delivery at the point of end use, and, as micrgrids become more prevalent, the PQR standards of the macrogrid can ultimately be matched to the purpose of bulk power delivery.

The MicroGrid structure assumes an aggregation of loads and microsources operating as a single system providing both power and heat. The majority of the microsources must be power electronic based to provide the required flexibility to insure controlled operation as a single aggregated system. This control flexibility allows the MicroGrid to present itself to the bulk power system as a single controlled unit, have plug-and-play simplicity for each microsource, and meet the customers' local needs. These needs include increased local reliability and security.

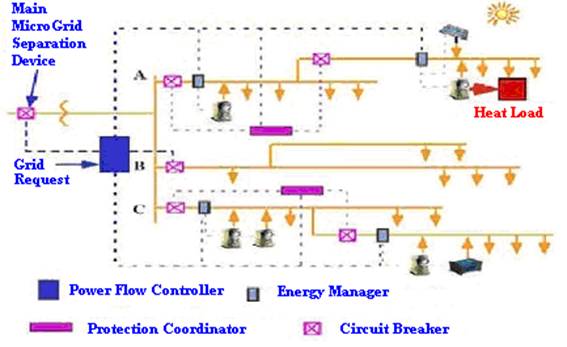

The figure shows the basic Microgrid Architecture. The electrical system has 3 feeders A, B and C. At the end of feeder there is collection of loads. This system is connected to the distribution system through separation device usually a static switch. The feeder voltage at the load are usually 415V or less. In Feeder A, there are several microsources such as PV (photovoltaic), microturbine (which use renewable energy and fuel sources as it input) and one microsource, which provides combined heat and power. Each feeder has a circuit breaker and power flow controller.

Power flow controller regulates feeder power flow at a level prescribed by energy manager. As load down stream changes, the local microsources increase or decrease their power output to hold the power flow constant. Feeders A and C are assumed to have a critical load and feeder B to have non-critical load. When there are power quality problems on the distribution system, the MicroGrid can island (isolate) itself by using the separation device. The non-critical feeder can be dropped using the breaker at B.

The key feature that makes the MicroGrid possible is the power electronics, control, and communications capabilities that permit a MicroGrid to function as a semiautonomous power system. The power electronics are the critical distinguishing feature of the MicroGrid, and they are discussed in detail below. This section describes some of the other technologies

whose development will shape MicroGrids.

Microturbines, currently in the 25-100 kW range, although larger ones are under development, may ultimately be mass-produced at low cost. These are mechanically simple, single shaft devices, using high-speed (50,000-100,000 rpm) typically with airfoil bearings. They are designed to combine the reliability of commercial aircraft auxiliary power units (APU’s) with the low cost of automotive turbochargers. Despite their mechanical simplicity, microturbines rely on power electronics to interface with loads. Microturbines should also be acceptably clean running. Their primary fuel is natural gas, although they may also burn propane or liquid fuels in some applications, which permits clean combustion, notably with low particulates.

Fuel cells are also well suited for distributed generation applications. They offer high efficiency and low emissions but are currently expensive. Phosphoric acid cells are

commercially available in the 200-kW range, and high temperature solid-oxide and molten- carbonate cells have been demonstrated and are particularly promising for MicroGrid application. A major development effort by automotive companies has focused on the possibility of using on-board reforming of gasoline or other common fuels to hydrogen, to be used in low temperature proton exchange membrane (PEM) fuel cells. Fuel cell engine designs are attractive because they promise high efficiency without the significant polluting emissions associated with internal combustion engines.

Renewable generation could appear in MicroGrids, especially those interconnected through power electronic devices, such PV systems or some wind turbines. Biofueled microturbines are also a possibility. Environmentally, fuel cells and most renewable sources are a major improvement over conventional combustion engines.

Storage technologies such as batteries, and ultracapacitors are important components of MicroGrids. Storage on the microsource’s dc bus provides ride-through capabilities during system changes. Storage systems have become more versatile than they were five years ago. Twenty eight-cell ultracapacitors can provide up to 12.5 kW for a few seconds.

Heat recovery technologies for use in CHP systems are necessary for MicroGrid viability, as is explained in the following section. Many of these technologies are relatively developed and familiar, such as low and medium temperature heat exchangers. Others, such as absorption chillers, are known but not in widespread use.

Environmentally, fuel cells and most renewable sources are a major improvement over conventional combustion engines. Microturbines should also be acceptably clean running. Their primary fuel will be natural gas, although they may also burn propane or liquid fuels in some applications, which permits clean combustion, notably with low particulates. NOx emissions, which are a precursor to urban smog, are mainly a consequence of combustion. Some traditional combustion fuels, notably coal, contain nitrogen that is oxidized during the combustion process, but even burning fuels that contain no nitrogen emits NOx, which forms at high combustion temperatures from the nitrogen and oxygen in the air.

Gas turbines, reciprocating engines, and reformers all involve high temperatures that result in NOx production. These devices must be carefully designed to limit NOx formation. Thermal microsources that effectively use waste heat can also have low overall carbon emissions that compete with those of modern central station combined-cycle generators. Human exposure to smog also depends on the location of smog precursor emissions. Since DER is likely to move NOx emissions closer to population centers, exposure patterns will be affected.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |