Published on Nov 30, 2023

Sonication is the act of applying sound (usually ultrasound) energy to agitate particles in a sample, for various purposes. In the laboratory, it is usually applied using an ultrasonic bath colloquially known as a sonicator. Sonication can be used to speed dissolution, by breaking intermolecular interaction. It may also be used to provide the energy for certain chemical reactions to proceed.

Sonication can be used to remove dissolved gases from liquids (degassing) by sonicating the liquid while it is under a vacuum.

Ultrasound is above the human audible range, part of the sonic spectrum that ranges from20 kHz to 10 MHz, is generated by a transducer in the Ultrasonic device that converts mechanical or electrical energy into high frequency acoustical (sound) energy. The sound energy is then fed to a horn that transmits the energy as high frequency vibrations to the liquid being processed. A wave propagates in a liquid through alternating cycles of compression and rarefaction.

The domestic waste water is mostly treated by biological process such as activated sludge process, aerobic pond, and anaerobic treatment. Waste activated sludge process is more efficient technology to meet stringent standard. It results in the generation of a considerable amount of activated sludge that has to be wasted . The expense for excess sludge treatment has been estimated to be up to 60% of the total operating cost of a wastewater treatment plant Moreover the conventional disposal method of land filling causes secondary pollution problems. Therefore, an interest in methods to reduce the volume and mass of excess sludge has been growing rapidly. . For the purpose of reducing the volume of sludge, anaerobic digestion has been widely used.

The anaerobic stabilization is a slow process. Therefore, long residence times in the digester and large digester volumes are required. Anaerobic degradation of particulate material and macromolecules is considered to follow a sequence of four steps: hydrolysis, acidogenesis ,acetogenesis, and methanogenesis. In the case of sewage sludge digestion, the biological hydrolysis has been identified as the rate-limiting step , e.g. break up of cell walls and disintegration of sludge flocks. Thus, the biological sludge needs to be pretreated to enhance the digestibility. The aim of such pretreatment is to rupture the cell wall and membrane to the release the intra and extracellular matter into the aqueous phase for subsequent degradation, and this process is called sludge disintegration. This sludge disintegration is performed by using the sonication which is one of the disintegration methodlogy.

The destruction of complex organic compounds can also be achieved by means of strong alkali during the alkaline pretreatment; the pH of the sludge is increased up to 12, maintaining this value for a period of time (normally24 h). This process may be used to hydrolysis anddecompose lipids, hydrocarbons and proteinsinto smaller soluble substances such as aliphaticacids, polysaccharides and amino acids Compared to thermal hydrolysis, alkaline pre-treatment is more efficient in terms of COD solubilisation. However, the global removal efficiency (together with the anaerobic digestion) is lower,because not all the soluble compounds formed are biodegradable. Positive and negative aspects of alkaline hydrolysis are:

(P) Low energetic requirements.

(P) Very good dewater ability of the final sludge.

(P) Modification of the sludge composition.

(N) Possible damage to the bacteria responsible for the microbiologic activities.

(N) Bad odor generation.

(N) Corrosion and fouling of the equipment.

(N) Higher COD in the final effluent due to the presence of non-biodegradable substances.

The biochemical sludge disintegration is based on enzyme activity that are either produced within the system (autolysis) or externally. The enzymatic lyses crack the compounds of the cell wallaby an enzyme catalyzed reaction. This process is of interest in combination with mechanical disintegration as well, because enzymes are alsolocated in the intracellular liquid Positive and negative aspects of bio-logical pre-treatment are:

(P)Low energy consumption.

(P)No stress on the equipment.

(N)High cost.

(N)The usage of enzymes to better the sludge stability is not clear.

(N)High generation of odors.

The WAS samples was sonicated using Sonics ultrasound unit,. The ultrasound unit has a maximum power output of 200W and operates at a Constant frequency of 20 kHz. The power input can be set independently from40 - 200 W. The amplitude can be also set independently from 20-100 %. The ultrasonic Equipment is shown in Figure 3.1

Ultra Sonic uses piezoelectric ceramics to generate ultrasound. When a piezoelectric ceramic is affected by an electrical field the dimension of the ceramic is altered. The repetition of the increase respective decrease of the ceramics dimension is created by the electrical fields changing polarity. The changes in the ceramics dimensions create ultrasound of a specific frequency. Three major components of an ultrasound system are the converter (transducer), booster and horn (sonotrode). A converter basically converts electrical energy into ultrasound energy (vibration). The booster is a mechanical amplifier that helps to increase the amplitude generated by the converter. The horn is a specially designed tool that delivers the ultrasonic energy to the sludge. Figure 3.2 shows the Arrangement of converter, booster and horn in a typical ultrasound system. The booster is designed and tuned to operate at a desired frequency.

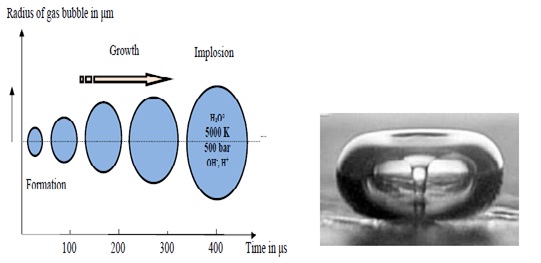

Ultrasonic disintegration is a well-known method for the break-up of microbial cells to extract intracellular material The impact of ultrasound waves on a liquid causes the periodical compression (Positive pressures) and rarefaction (negative pressures)of the medium. During the low-pressure cycle, the ultrasonic waves create small vacuum bubbles in the liquid that collapse violently during a high-pressure cycle. This phenomenon is termed cavitation. Micro bubbles occur in rarefaction due to the negative pressure. These micro bubbles also known as cavitation bubbles, essentially containing vaporized liquid and gas that was previously dissolved in the liquid. As the wave fronts propagate, micro bubbles oscillate under the influence of positive pressure. Cavitation bubbles first grow in size until reach resonant bubble size within a few microseconds and then violently collapse when they reach its critical size.

The ultrasonic disintegration method of sludge treatment is very innovative in the field of waste activated sludge treatment obtained from domestic waste water plant .It reduces the digester volume .It reduces the retention time by 25% with comparison to without ultrasonication process .It reduces, amount of sludge produced by 30% in comparison to conventional aneorobic digestion. hence saves relative amount of sludge disposal cost. There is appreciable increase in methane production from ultrasonic treated waste with respect to different ultrasonication time and power inputs .it may go as high as 152 % when power of 190 watts is applied for 240 sec. It also destruct volatile and non volatile impurities present in water by mechanism of cavitation. Apart from this it controls the foaming of sludge by killing filamentous bacteria and other pathogens. Due to these reasons this method of sludge treatment can become crucial way of waste sludge treatment.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |