Published on Nov 30, 2023

The Idea of Dynamic Architecture was born with the desire to have buildings that adjust themselves to life, that are part of nature. In fact, our buildings, in which each floor rotates separately, change their shape continuously and never look the same.

I call them “Buildings designed by time, shaped by life”. Imagine a skyscraper that can revolve according to tenants’ needs and whims, allowing them to decide their own light exposition and view. In fact, these buildings are part of nature, inserted in the environment. During the first phases of design I understood therefore that they are by nature sustainable buildings. In fact, they become part of environment, they are made of natural materials green as they save energy, but not only as they produce wind energy and what can be more important today then saving our planet?

Architecture seems today as an expression of artistic imagination as most architects are competing in designing buildings that can become iconic due to their particular shapes. Design is of course an important value in our society, it takes care of a part of our life style…but above all we should really care for our quality of life and quality of life has different values.

In fact, architects could at the end of the planning process take care also for the harmony of the shapes. But only after they satisfy the previous task, the first commands. Today, instead, most architects exchange their trade concept with sculptures as they make sculptures in the wrong scale. Buildings are different things as they are the shell around our space and should be therefore satisfying our needs, therefore they should make sense being designed and built, according to a specific list of preferences. I believe that the six commands of Architecture are ranking in importance as follows:

1. Economical Feasibility

2. Functionality

3. Environmentally sound

4. Quality & Engineering

5. Maintenance

6. Design

The above are the principals of sustainability.

The rotation of these buildings indeed could be seen as a gimmick, but not so! It all started with the desire to see the view around us, of adjusting our self to the season, to follow the sun, of having a house part of nature.

I consider our Dynamic Architecture towers to give also sense of time, of movement to life, rotating apartments may give a different sense to our life and create a different space around us.

Above all, these buildings are sustainable, as will be hereby described. Dynamic Architecture buildings keep modifying their shape. As each floor rotates separately, the form of the building changes constantly; you may not see the same building twice.

Dynamic architecture marks a new era in architecture. This new approach, based on motion dynamics, is in fact a challenge to traditional architecture that until now was based on rigid buildings…joking, I call the not-moving buildings tombstones… buildings should start being part of the universe.. and therefore moving…dynamic…. How could one think that homes in digital area will be immobile as our grandmother house?..., Dynamic Architecture buildings will become the symbol of a new philosophy that will change the look of our cities and the concept of living. From now on, buildings will have a fourth new dimension TIME. Buildings will not be confined to rigid shapes; construction will have a new approach and flexibility. Cities will change faster than we ever imagined.

This fourth dimension has been the essence of my work so far. The concept has already generated considerable interest internationally, from political leaders and city councils. The homes we live in and the way we live are also set to change drastically with this innovative architecture. Our buildings will no more remain the ‘fossilized imagination' of the architect; they will change, constantly bringing new views and experiences to us with time; nor can the architect's pencil impose an environment on us. Each building will have its own future and will gain freedom.

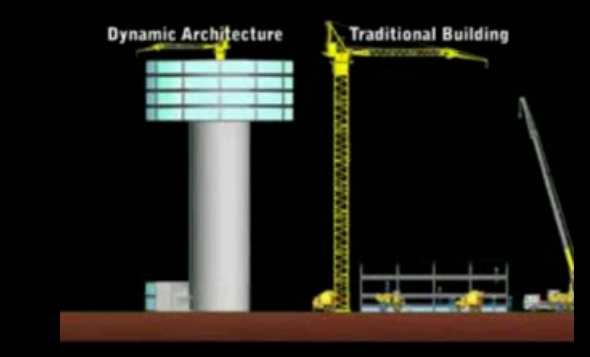

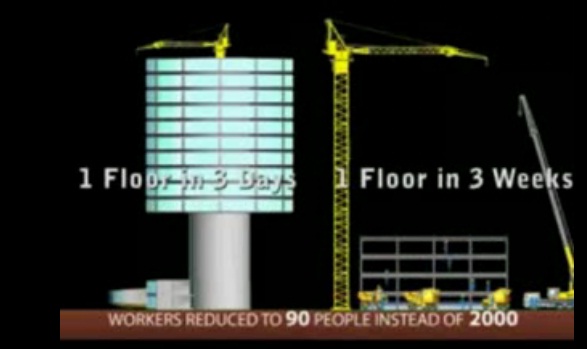

Dr. David Fisher’s revolutionary Dynamic Tower, the first building in motion which is the first skyscraper to be entirely assembled in a factory from prefabricated parts, factory made buildings will offers the advantages of any modern industrial product, it saves energy, reduces construction time and dramatically cuts building costs.

The prefabricated units arrive at the building site ready for quick and efficient installation, this approach known as the Fisher Method also requires far less workers on the construction site than traditional traditionally, In fact each floor of the building can be completed in only seven days and units can also be customized according to the owners’ needs and styles.

Each individual unit will be completely finished at the new Rotating Tower factory in Italy and exported worldwide, it will be equipped with all necessary plumbing and electric systems including all finishing from flooring to ceilings, bathrooms, kitchens, cabinets, lighting and furniture.

The preassembled units are simply hooked to each other mechanically, this results in environmentally clean construction sites, avoiding unloading of materials, waste, noise and pollution, there will be less risk of accidents to construction workers, and construction time will be reduced by over 30 percent. due to their particular construction method, prefabricated buildings will also be easy to maintain and repair, the building’s maintenance facility, type of materials used, and the quality control employed will also make them more durable than any traditional structure.

Since the ancient Egyptians built the pyramids not much has changed in the world of building construction, workers placed a stone on top of another, and brick on top of brick, in 1889, the use of steel was introduced into construction for the Eiffel Tower in Paris, and beginning in 1905 reinforced concrete was used, with the start of the Industrial Revolution in 1780, products began to be made in factories using industrial methods, but today buildings are still done on site as they were 4,000 years ago.

“Almost every product used today is the result of an industrial process and can be transported around the world, from cars and boats to computers and clothing, factories are chosen for their ready access to materials, production technology, inexpensive labour, efficiency, and other conditions that result in high quality at a relatively low cost,” Dr. Fisher noted.

“It is unbelievable that real estate and construction which is the leading sector of the world economy, is also the most primitive, for example most workers throughout the world still regularly use trowels that was first used by the Egyptians and then by the Romans, buildings should not be different than any other product, and from now on they will be manufactured in a production facility,” Dr. Fisher stated. The Dynamic Tower represents the future of architecture, resulting in a new era of living that will benefit both man and nature.

Renowned Italian architect Dr. David Fisher is the creator of the Dynamic Tower, a building in motion. He has spent more than 30 years working to redefine the technical and technological extremes of buildings in cities like London, New York, Moscow, Hong Kong, Paris and Dubai, he graduated with honors from the University of Florence where later he served as a professor of architecture and structural engineering.

Fisher is the creator of the world’s first building in motion, the Dynamic Tower heralds a new era of architecture buildings in motion that will challenge traditional architecture to become the symbol of a new philosophy that will change the look of our cities and the concept of urban living.

I think we all are aware that construction technology hardly changed in the course of the years. It was clear to me on the other hand that we can use for this building, that I tend to call “a machine for living”, many other technologies that exist in other fields.

The phases of design got me and our engineers, taking part in the design of the Rotating Tower, very much involved with our “partners” industries such as Bosch. We tried to apply technology existing in different fields such as air space, trains, massive machines and tools, the large telescopes, bridges, off shore platforms and cranes.

The rotation of the floors is done with steel bearings and combination of air-cushion, allowing the floors to rotate smoothly and with no vibrations.

There is limited power of about 4 KW required to rotate a floor. The drive system is situated in the base of each floor so it can not be seen and in the same time it allows easy maintenance when required.

The structure is based on a reinforced concrete core of about 22mt diameter that carries all the vertical loads. The floors will be all made of steel structure, becoming a monolithic platform, with a cantilever up to about 15 meters.

The floors will be connected to the core in a way that will allow a continuous rotation to either direction, with no vibrations or noise.

This architecture is revolutionary even in the way it's built. It is in fact the first building produced in a factory, apart from the concrete core. It's produced of complete luxury units in a factory, including all plumbing, electrical, air conditioning and installed on the concrete core right on location. This read made implementation offers high quality finishing, high quality control and the use of a very few workers on site, with a real cost, life risks and time savings. Besides, this architecture made of single separated floors offer higher seismic resistance than any other normal building. Dynamic Architecture is designed for better living even before it's finished.

The readymade technology allows a revolutionary implementation which is the quickest way to build a tower: building time is reduced from 30 to 18 months. The revolutionary readymade technology, plus the fact that it moves to the wind, allows the building to be 1.3 times more resistant to earthquakes.

The Dynamic Tower, the world’s first building in motion, takes the concept of green buildings to the next level where it will generate electricity for itself as well as other nearby buildings, making it the first skyscraper designed to be self powered. The building generates electricity from wind turbines mounted horizontally between each floor, eighty story building will have up to seventy nine wind turbines, making it a true green power plant while traditional vertical wind turbines have some environmental negative impact, including obstruction of views and the need for roads to build and maintain them, the Dynamic Tower’s wind turbines are practically invisible and extremely quiet due to their special shape and the carbon fiber material they are made of.

Another environmentally green element of the Dynamic Tower is the photovoltaic cells that will be placed on the roof of each rotating floor to produce solar energy, approximately 20% of each roof will be exposed to the sun, so a building that has 80 roofs will equal the roofing space of 10 similar size buildings. In addition, natural and recyclable materials including stone, marble, glass and wood will be used for the interior finishing.

Energy will also be saved during construction, which involves pre-fabricating individual units in a factory, this Fisher Method not only reduces construction time, but it also results in a cleaner construction site with limited noise, dust, fumes and waste, the shorter building time also results in a less energy consumption than traditional construction methods.

It has been calculated that in addition to the cost savings of up to 20% compared to those of traditional building methods, the construction time will be reduced of 30%. The Method will allow the completion of a 70-floor skyscraper within 18 months (nowadays it would take around 30 working months). Furthermore, the “assemblage” of the Rotating Tower would require the presence of approximately 90 people (specialized workers, technicians and engineers) in the building site, instead of over 2 000 people in the traditional ones. The Method will turn the site into a place where the modules are only assembled because the structural work has already been completed in the factory. The structural concept of the building is very simple – in fact, the only structural element is a single centre core made of concrete. It is faster, less expensive then hundred of beams, columns and joints and also more sound as it is quite a homogeneous structure with no wick connections.

In addition, it will be possible to customize individual apartments according to owners' needs and style. Due to the industrial process, the apartments will offer excellent design and an endless variety of customizations (see Figure 3) mI wish to underline that modules, as a new industrial structure, can easily offer luxury standards of living and excellent structure quality.

The quality standards, from the structural parts to the fittings and finishing, can easily be guaranteed since the modules are manufactured in an industrialized structure, and not in a building site where monitoring can be difficult

Another strong point of the “Fisher Method” is safety in the working place. Building site workers will be able to operate in comfortable and functional environmental conditions because the various assemblage

(Rather than construction) phases will follow smart, time-saving, well-organized sequences. The industrialization of house-building in fact is based on the optimization of the manufacturing cycle and will turn house-building technique into an industrial model.

Thanks to this new Method, the Rotating Tower building site will definitely offer outstanding environmental advantages to the cities: traditionally huge, polluted, unsafe building sites will become Smart Sites, comparatively smaller, ecological and safer. Considering that the modules have been pre-assembled in the factory, all the negative factors linked to traditional sites will disappear: big space around the building, endless loading and unloading, debris, waste material, noise and traffic. The modules for the Rotating Tower will be assembled in dedicated industrial parks where manufacturers of high standard building materials will gather to work on the common project. The first industrial park will be created in Italy, and it is easy to foresee that the most important Italian manufacturers of interior design furniture and accessories will be the official suppliers of the Rotating Tower apartments and hotels, giving a new impulse to “Made in Italy” brands. In the future these dedicated industrial parks will become possible in any country where a Rotating Tower will be built.

The Dynamic Tower in Dubai is the first Building in Motion to be constructed in the world, and it will herald a new era of architecture and become a symbol of Dubai, the city of the future.

The Dynamic Tower in Dubai will have 80 floors, and will be 420 meters (1,380 feet) tall, Apartments will range in size from 124 square meters (1,330 square feet), to Villas of 1,200 square meters (12,900 square feet) complete with a parking space inside the apartment. The first 20 floors will be an offices, floors 21 to 35 will be a luxury hotel, floor 36 through 70 will be residential apartments, and the top 10 floors will be luxury villas located in a prime location in Dubai, it is destined to become the most prestigious building in the city.

The Dynamic Tower in Dubai will be the first skyscraper to be entirely constructed in a factory from prefabricated parts, it will require only 600 people in the assembly facility and 80 technicians on the construction site instead of 2,000 workers on a similar size traditional construction site and Construction.

His Highness Sheikh Mohammed Bin Rashid Al Maktoum ruler of Dubai and Vice President of the United Arab Emirates, is considered by many to be a true visionary of the future, Dr. Fisher’s dreams for the Dynamic Tower in Dubai were inspired by His Highness who said “Do not wait for the future to come to you…face the future

1. Dynamic Architecture (Rotating Tower)-Dr. Arch. David Fisher

2. Www.Google.com

3. Www.Youtube.com

| Are you interested in this topic.Then visit the below page to get the full report |