Published on Apr 02, 2024

Aim is To investigate foaming capacity of different washing soap and effect of addition of sodium carbonate on them. Soaps and detergents are cleaning ingredients that are able to remove oil particles from surfaces because of their unique chemical properties.

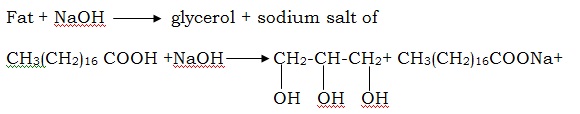

Soaps are created by the chemical reaction of a jetty acid with on alkali metal hydroxide. In a chemical sense soap is a salt made up of a corboxylix acid and an alkali like sodium of potassium. The cleaning action of soap and detergents is a result of thrill, ability to surround oil particles on a surface and disperse it in water.

Bar soap has been used for centuries and continues to be an important product for batching and cleaning. It is also a mild antiseptic and ingestible antidote for certain poisons. SOAP Soap is a common term for a number of related compounds used as of washing clothes or bathing. Soaps are sodium or potassium salts of higher fatty acids such as stearic acid (C17 H35 COOH), palmittic acid (C15 H31 COOH) and oleic acid (C17H35 COOH) they have the general formula RCOONa and R COONa. Soap is produced by a saponification or basic hydrolysis reaction of a fat or oil. Currently sodium carbonate or sodium hydroxide is used to neutralize the fatty acid and convert it to the salt..

Although the reaction is shown as one step reaction, it is in fact two steps. The net effect as that the ester bonds all broken. The glycerol turns back into an alcohol. The fatty acid is turned into a salt due to the presence of abasic solution of NaoH. In the carboxyl group, one oxygen now has a negative charge that attacts the positive sodium ion. A molecule of soap consists of two parts.

a) Alkyl group – it is oil soluble

b) Corboxyl group – It is water soluble

The type of fatty acid and length of the carbon chain determines the unique properties of various soaps. Tallow or animal fats give plimarily sodium stearate (18 carbons) a very hard, insoluble soap. Fatty acids with longer chains are even more insoluble. As a matter of fact, 3inc stearate is used in talcum powders because it is water repellent. Coconut oil is a source of lauric acid (12 carbons) which can be made into sodium lourate. This soap is very soluble and will lather easily even in sea water. Fatty acids with only 10 or fewer carbons are not used in soaps because they irritate the skin and have objectionable odors

(a) Apparatus Five 100ml conical flasks, five 20ml test tubes, 100ml measuring cylinder, test tube stand, weight box and stop watch.

(b) Chemicals Five different samples of soap and distilled water.

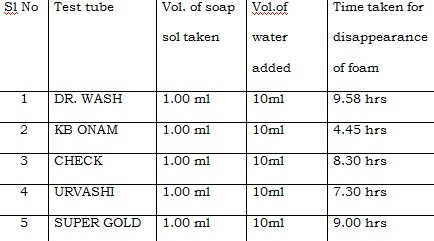

There is no quantitative method for the determination of foaming capacity of a soap. The foaming capacity of soap depends upon concentration of soap in the sample. Solution of different soap are prepared by dissolving their equal weights in equal volumes of distilled water. These solutions are shaken vigorously to produce foam and then they are allowed to stand. Time taken for the disappearance of foam are measured for different samples. Longer the time taken for the disappearance of foam in a given sample of soap, greater is its foaming capacity

Take five 100ml conical flasks and lobel them as A,B,C,D,E.

Take 50ml of water in each conical flask and then add 2g of different samples of soap to each flask.

Warm to dissolve and get a clear solution. Arrange five test tubes on a test tube stand labelled as A,B,C,Dand E.

Take ICC of the soap solution from each conicol flask ad to the corresponding test tube.

Shake the test tube for 1 minute by covering its mouth by the thumb.

Foam will be formed in the test tube. Start the stop watch and note the time taken for the disappearance of foam.

Repeat the same procedure for the test tubes B, C,D and E.

Shaking each tube with the same force and noting the time taken for disappearance of the foam

• Foaming capacity of soap is maximum in distilled water as compared to that in tap water.